Fabrication process:

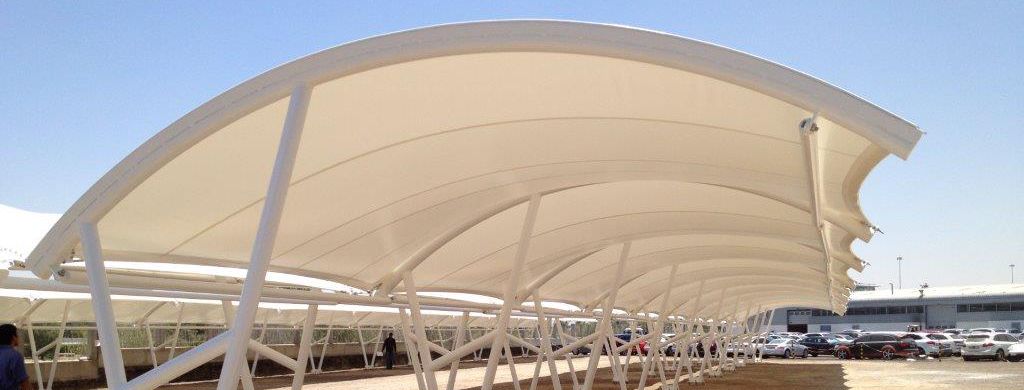

Shade design:

-

Fulfilling customer's expectation is our target and so we are designing all our shade structures and sketch it in a presentation for our clients as to expect the shade style and effectiveness.

-

Also our sales team will help you to chose among our shading products and will recommend based on experience what shade design is most fitting to your case.

-

If you are starting a new project or building your own residential unit it's very important to chose the place of the shade, we can help you with shadow study to give you the most benefit out of shaded areas.

Steel fabrication:

-

All Shade Structures are engineered and designed to meet a 90 mph wind load.

-

All our steel structures are pre-engineered and according to international standards.

-

Our industrial methodology is to construct the shade on bolted structure without welding on site.

-

We are using brand new steel sections and bolts almost of one size.

-

All our steel sections are painted by anti rust paint and then top coat paint as the customer choice.

Sewing & welding:

-

All fabrication process is done under one roof starting from steel fabrication, sewing, checking, shipping

-

We are using special threads that doesn’t decay from sun and have high elongation and tensile strength

-

For PVC membrane structures we are using Liester Uniplan hot air welding machine for perfect welding

Gutterman threads:

Special sewing thread developed and bonded for outdoor maritime applications. UV stability coupled with higher colour fastness and seawater resistance ensure particularly durable seams under extreme conditions with optimal processing properties.

Liester welding:

We are using swiss technology for PVC welding ensuring high quality welding with international standards.

Success story with Liester welding equipment:

Installation:

Our skillful team of installation has a very long experience in shades installation especially that we have a wide range of shade products and each one varies from others.

We are using special tools for installation like tension devices and turnbuckles, steel plate connections to the fabric in order to get the fantastic good looking shades.

Regularly each steel post in commercial designs will need construction works to make the appropriate foundation for the column which will be around 1 cubic meter of concrete, either to make it yourself if you have construction experience or we will get a contractor with cost to get it done.

Warranty:

-

Our superior high engineered shade structures are designed to last and come with a 5 years steel warranty and 1 year warranty on shade netting against problems in manufacturing or installation.

-

We also back this with our long-term experience as a market leader delivering you premium products to secure your investment.

-

A warranty certificate will be handed to our clients after shades installation and final delivery.